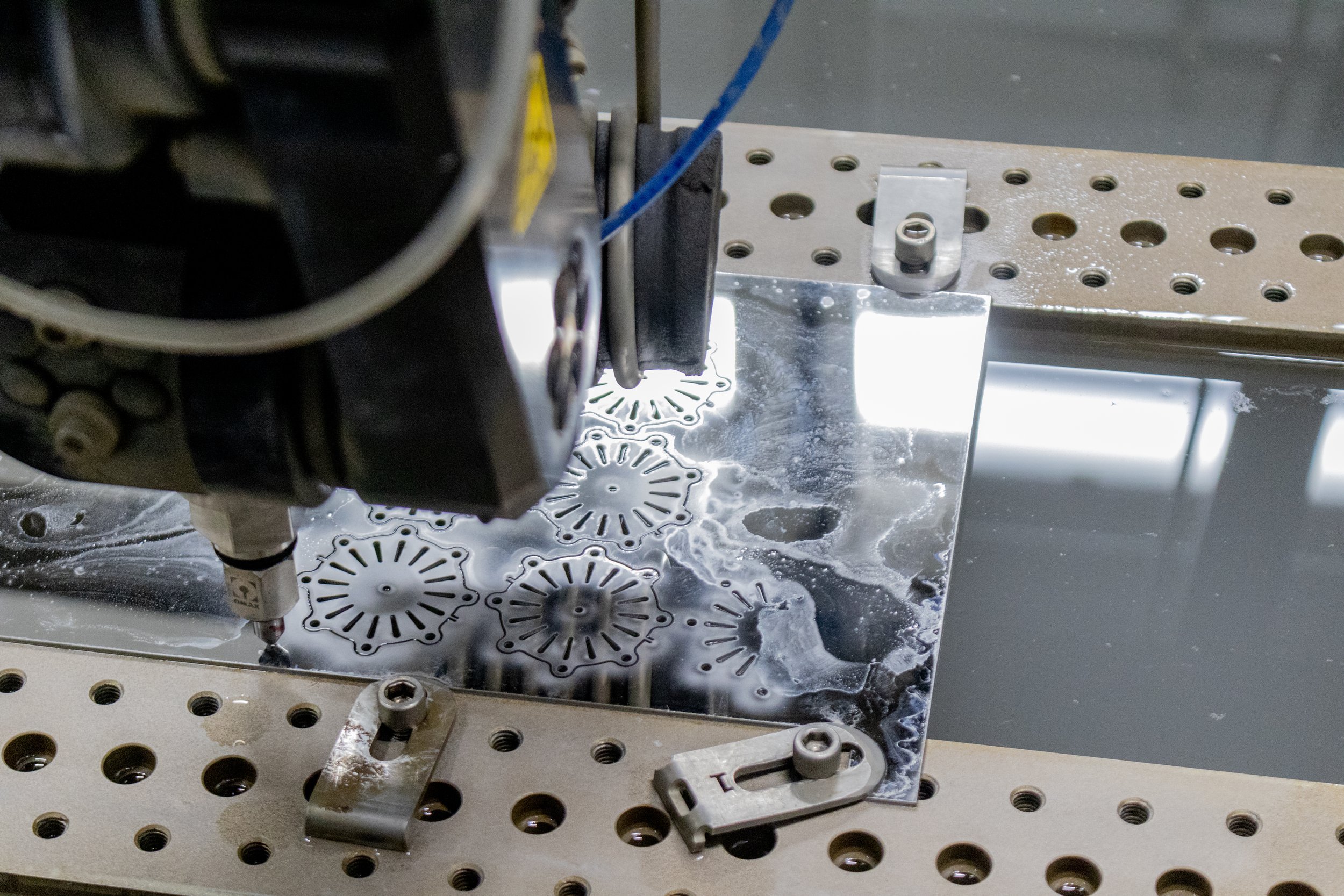

Micro Waterjet

INTRICUT is proud to be the first Canadian company to offer custom MICRO Waterjet Cutting services. The ultimate solution for manufacturing prototypes, our Micro Water Jet cutting service combines the benefits of conventional waterjet cutting with a level of precision approaching Wire EDM cutting.

Benefits of Micro Waterjet Cutting Include:

Taper and burr-free edge finish.

No Heat Affected Zone on cutting edges allows for secondary machining processes.

Low Pressure piercing capabilities to avoid delamination in layered materials.

Thickness capabilities of (13mm thru .13mm).

5-axis Kerf elimination technology and taper cutting up to 10 degrees.

Capable of positioning accuracies of .012mm and cutting accuracies down to .025mm.

Micro Kerf Size of .38mm diameter for machining tiny features.